how does vapor honing work

Treat the surface to make it metallurgically clean prior to electro-polishing electro-plating or other coating processes. Liquid Vapor Honing.

Vapor Hone Up And Running Bike Builds Motocross Forums Message Boards Vital Mx

Vapor blasting is a superior process with significant advantages over traditional dry sandblasting.

. On aluminum it leaves a finish that looks almost like paint. Vapor honing is a finishing process that utilizes water and various types of fine media to restore parts to OEM finish. Vapor honing is also a great choice for removing very tiny scuffs and tool marks as well as for applications that need a satin-smooth finish.

With water serving as lubricant the pressurized slurry mixture wont scar heat or warp the original surface of the part allowing even delicate internal engine components to be vapor honed. The Liquid Vapor Honing process is applied to metals for the following reasons. Water abrasive and compressed air a.

Well how it works is t. Before you start the cleaning process you need to pick the type of abrasive youll use to clean your part. This allows for sufficient degrees of freedom with respect to the tool assembly.

To remove imperfections such as heat treat scaling you add fine abrasives to the water then sprayed onto the material at great speed. For this purpose the tool is double hinged to the honing spindle. For this reason vapor honing eliminates negative characteristics such as media impingement.

Vapor honing is a wet blasting process which uses very fine glass beads and water under air pressure. Wet blasting vapor blasting is a process for removing contaminants from a surface or finishing a surface using pressurized water and abrasive blast media. Sandblasting on the other hand restores surfaces with the use of impacts and sheer force.

Vapor honing smooths surfaces with the use of abrasive media and water. Vapor blasting is also commonly known as wet blasting liquid honing vapor honing dustless blasting or slurry blasting. Instead of dry abrasive media used in sandblasting it uses a combination of water compressed air detergents with finer and gentler media to remove oxidized metal and corrosion.

A specially designed high volume pump mixes abrasive media with water. Vapor Honing often known as wet blasting is a technique used to polish precise surfaces. Makes your old parts look like new.

No media is impregnated into the component nor is there any dust created by the break-up of media unlike dry blasting where the finish is produced by sheer force of media impact. Vapor honing also referred to as vapor blasting or wet blasting is a surface refinishing process used to clean and restore surfaces. It leaves a smooth satin finish and is much more gentle to the surface than dry sand or glass bead blasting.

Ad Browse discover thousands of brands. The key to vapor blasting is that the finish is produced through the flow of water borne abrasive giving a finer finish due to the flushing action of the water. Bore axis and tool axis are identical.

Its perfect for restoration work because it makes the metal surface look like new but does not remove metal like. Vapor honing can be used on almost any surface found on a motorcycle or car including gloss plastic. While it can handle a wide variety of materials it gives a excellent finish aluminum zinc brass and magnesium.

By suspending fine abrasive media in water and detergents the blasted surface is left with an attractive satin finish that is smooth and almost polished due to a peening-effect that doesnt leave fingerprints like sandblasted parts do while being more resistant to future. Read customer reviews find best sellers. How Does It Work.

Remove machining or directional polish lines or marks on such objects as molds and dies for metal plastics or rubber. Are favorite application is carbs for the finish it provides. This treatment is typical of a conventional dry blasting procedure.

If the abrasive media is mixed with water and pressurized in a pressure. How Does Vapor Honing Work. As mentioned the honing stones can be moved against the bore wall by the radial feed.

Also known as wet abrasive blasting vapor blasting vapor honing dustless blasting or slurry blasting. Through the feed motion the tool is centered in the bore. Wet Blasting is an industrial process in which pressurized wet slurry is applied to a surface for various cleaning or finishing effects.

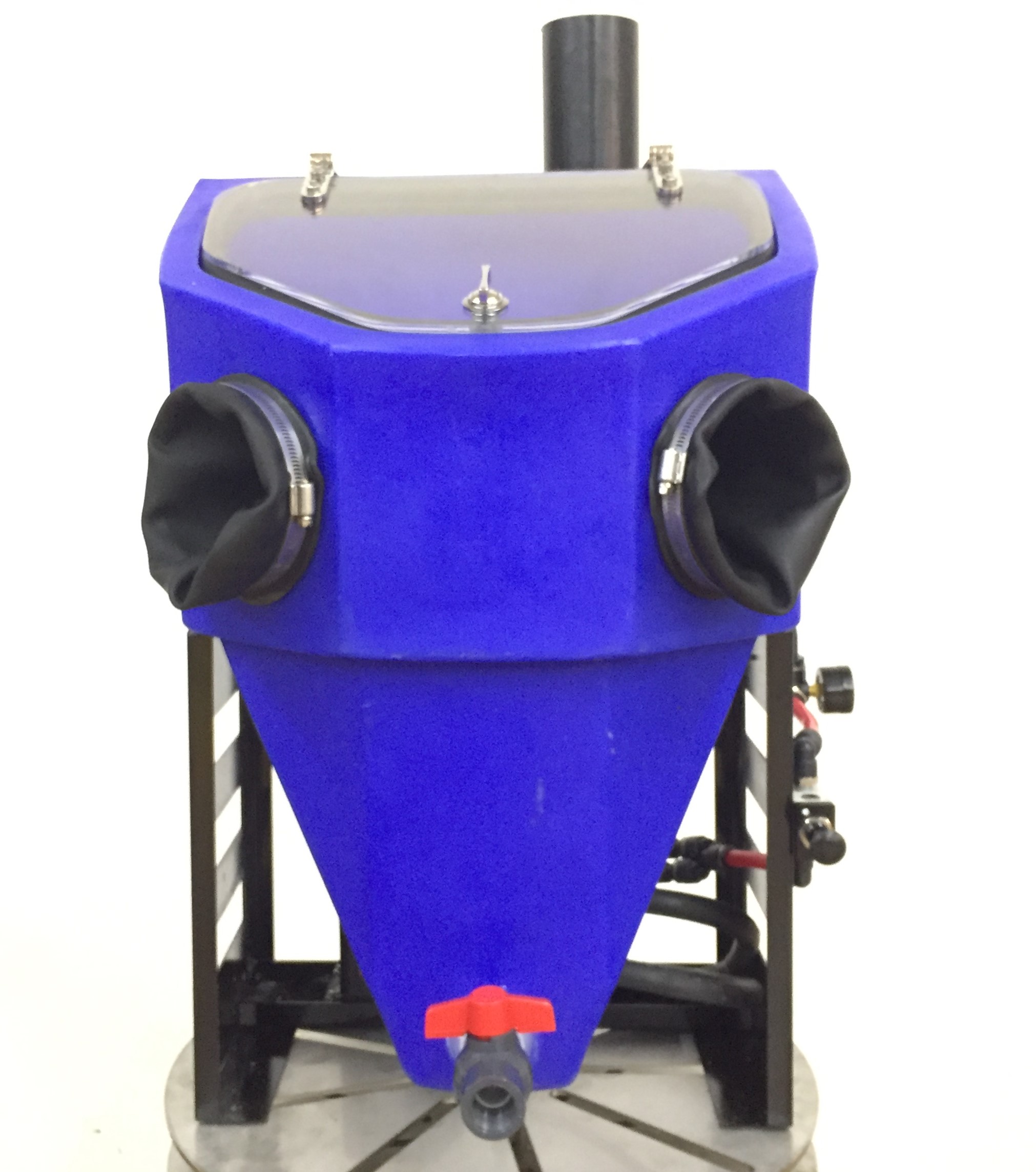

Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa

Vapor Honing Technologies Lilhonda Com

What Is Vapor Blasting Answering Your Wet Blasting Faqs

What Exactly Is Vapor Honing 5 Things You Should Know

Vapor Blasting What It Is Costs And Shipping

Vapor Hone 1000 Wet Blasting Equipment Blast Wash Systems

How Good Is The Micro Hone Vapor Honing Technologies Youtube

Vapor Blasting In Your Home Shop Vapor Honing Technologies Youtube

What Is Vapor Blasting Answering Your Wet Blasting Faqs

Micro Vapor Hone Benchtop Vapor Hone With A Small Footprint

Vapor Honing An Engine The Ultimate Guide

Slurry Blasting Vapor Blasting Equipment For Sale Vapor Honing Technologies

Cleaning Pistons Using Vapor Blasting Vapor Honing Technologies Youtube

Vapor Blasting Services Wet Blasting Vapor Honing Technologies